|

| as seen at stata; click to see larger pic |

when i saw this in stata a few days ago i legitimately wondered for a few seconds which way this was color-coded until I saw a note (cropped out in this pic), which made me smile. At MIT and hopefully in the general world the imperfect gender ratios are really not so noticeable unless you're looking for it. MIT is wonderful (I say this now because I have no finals this term, all project classes that I loved even if I didn't do as well as I'd've liked)

Anyway, there were no citations! so I decided to go off and investigate on my own and treat it as a data visualization exercise (hi, upcoming IAP / startlabs / c2c / metrify).

EDIT: Derp! I data-failed. You can see civil/environmental engineering (course 1 -- s

ee http://web.mit.edu/catalog/subjects.html if you're confused by the numbers) is definitely off. : / messed up copying and pasting somewhere. Will redo this for realz one day (they have data for multiple years, I want to clean it up automatically).

|

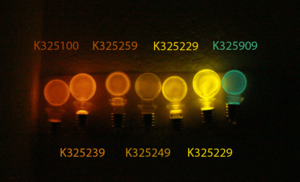

| sorted by % |

|

| sorted by course number |

~~

http://www.quora.com/MIT-1/What-is-the-gender-ratio-for-each-of-the-majors-at-MIT

data source

Here's the data I used (I should just email them for the csv's, but I thought this would be a simple data scraping exercise):

http://web.mit.edu/registrar/stats/gender/index.html

http://web.mit.edu/registrar/stats/yrpts/index.html

What tripped me up is that the women vs. everyone listing of majors is ever so slightly off, and I have to decide how many distinctions I want to make. Do I really care about 2 vs 2A? not really. If I care about 6-1 vs 6-2 vs 6-3, do I just drop 6-7?

assorted google spreadsheets of data from those sources

cleaned data for charts

https://docs.google.com/spreadsheet/ccc?key=0Atr0HZeoMbmgdHFNZU5mbEdYU2VIOE1BUTRLZHJJVkE

raw data sorted for female / undergards

https://docs.google.com/spreadsheet/ccc?key=0Atr0HZeoMbmgdFg0Vk14RW9JQjJtSFFsMXJBZ2hnSEE

raw scraped html table data

https://docs.google.com/spreadsheet/ccc?key=0Atr0HZeoMbmgdFYzNUdEN2NKM2lGbHV6OVN4YkJNTmc

where i tried to (see script editor) automagically clean up the data and failed:

https://docs.google.com/spreadsheet/ccc?key=0Atr0HZeoMbmgdFRkSXp5SW9teEJiT0t5U2FJeTBUVnc&hl=en_US#gid=0

the

google apps code

I used for that last gdoc

function loadImport() {

var ss = SpreadsheetApp.getActiveSpreadsheet();

var sheet = ss.getActiveSheet();

var data_sskey = "0Atr0HZeoMbmgdFYzNUdEN2NKM2lGbHV6OVN4YkJNTmc";

var row_init = "13";

var col_ug = "G";

var col_grad = "M";

var col_total = "O";

var col_courseName = "A";

var col_courseNumber = "Q";

var cols = [col_ug, col_grad, col_total];

//create arrayformulas for copying selected data over

//e.g. =ImportRange("0Atr0HZeoMbmgdFYzNUdEN2NKM2lGbHV6OVN4YkJNTmc","Women!G13:G")

//Add Course Names

var finalRanges = [ '=ImportRange("' + data_sskey + '","Women!' + col_courseName + "13:" + col_courseName+ '")'];

//Add Enrollment Data in alternating female / all

for (var i = 0; i < cols.length; i++){

femRange = '=ImportRange("' + data_sskey + '","Women!' + cols[i] + "13:" + cols[i]+ '")';

finalRanges.push(femRange);

everyoneRange = '=ImportRange("' + data_sskey + '","Everyone!' + cols[i] + "13:" + cols[i]+ '")';

finalRanges.push(everyoneRange);

}

//Add Course Numbers

finalRanges.push('=ImportRange("' + data_sskey + '","Women!' + col_courseNumber + "13:" + col_courseNumber+ '")');

// Sets the column header names to match copied data.

//sheet.getRange("A1").setValue(range);

var columnNames = ['Course Name', 'Fem UG', 'All UG', 'Fem Grad', 'All Grad', 'Fem Total', 'All Total', 'Course Number'];

var headersRange = sheet.getRange(1,1,1,columnNames.length);

headersRange.setValues([columnNames]);

//var dataRange = sheet.getRange(2,1,1,columnNames.length);

for (var j = 0; j < columnNames.length; j++){

sheet.getRange(2, j+1).setValue(finalRanges[j]);

}

}

//method getRange(row, column, optNumRows, optNumColumns)

Google Docs Scripting Tutorials

An excellent step-by-step free tutorial on ImportXML (similar to importHTML that I used), how I heard of xpath (which I didn't end up need to use due to importHTML magic):

http://www.distilled.net/blog/distilled/guide-to-google-docs-importxml/

other useful tutorials I referred to

http://blog.ouseful.info/2008/10/14/data-scraping-wikipedia-with-google-spreadsheets/

http://blog.fastfedora.com/2011/08/how-to-use-open-apis.html *shudders* speaking of government apis, I really should be less terrible and fix my github codeforamerica repos which I left half-finished. AUGH. I FAIL. This is why I haven't applied to any jobs yet. Upcoming: post on why you shouldn't hire me (with the caveat that I feel okay listing these because these are past mistakes that I don't intend to make again).

http://blog.ouseful.info/2010/02/15/creating-a-winter-olympics-2010-medal-map-in-google-spreadsheets/

eeee shiny

http://pipes.yahoo.com/pipes/

I also attempted to use google fusion tables but did not have a good experience.

http://code.google.com/googleapps/appsscript/articles/writing_spreadsheet_data.html

http://code.google.com/googleapps/appsscript/service_spreadsheet.html

To investigate:

http://www.propublica.org/nerds/item/using-google-refine-for-data-cleaning